Top-quality parts manufacturer for SLA technology

By:Admin

In the world of advanced manufacturing, one company stands out as a leader in the production of Sla parts. With a commitment to quality and innovation, this manufacturer has established a reputation for delivering high-performance parts that meet the demands of the modern industry.

Founded in [year], the company has quickly become a trusted partner for businesses across a wide range of industries, including aerospace, automotive, medical, and consumer electronics. The company's state-of-the-art facilities and cutting-edge technologies allow them to produce Sla parts with incredible precision and efficiency, making them a preferred supplier for many leading companies.

One of the key reasons for the company's success is its dedication to continuous improvement and investment in advanced manufacturing technologies. The company has made significant investments in the latest Sla printing equipment, ensuring that they are always at the forefront of innovation in this rapidly evolving field. This commitment to technology has allowed them to expand their capabilities and offer a wider range of Sla parts to their customers.

The company's team of expert engineers and technicians is another critical factor in their success. With a deep understanding of the Sla manufacturing process, they are able to provide invaluable insights and expertise to their clients. This level of technical knowledge and experience sets the company apart from its competitors and allows them to consistently deliver superior quality parts to their customers.

Furthermore, the company's dedication to quality is evident in their stringent quality control processes. Every Sla part undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and reliability. This commitment to quality has earned the company a reputation for excellence, and they are trusted by their customers to deliver parts that consistently exceed expectations.

In addition to their focus on quality, the company is also committed to sustainability and environmental responsibility. They have implemented eco-friendly practices in their manufacturing processes and are constantly exploring new ways to reduce their carbon footprint. This commitment to sustainability has not only allowed the company to minimize its impact on the environment but has also resonated with customers who prioritize working with environmentally conscious suppliers.

Looking ahead, the company is poised for continued growth and innovation. They are continuously exploring new opportunities to expand their product offerings and improve their manufacturing processes. By staying at the forefront of Sla manufacturing technology, they are well-positioned to meet the evolving needs of their customers and drive the industry forward.

In conclusion, this Sla parts manufacturer has positioned itself as a leader in advanced manufacturing technologies. With a focus on quality, innovation, and sustainability, the company has earned the trust and respect of customers across a wide range of industries. As they continue to invest in new technologies and expand their capabilities, they are likely to remain a top choice for businesses seeking high-performance Sla parts.

Company News & Blog

Complete Guide to Plastic Injection Molding for Mold Making

Mold Plastic Injection, a leading company in the plastics manufacturing industry, has recently announced the launch of a cutting-edge new injection molding system that is set to revolutionize the way plastic products are manufactured. With a focus on innovation and sustainability, Mold Plastic Injection is dedicated to providing high-quality plastic injection molding solutions to a wide range of industries.The new injection molding system, developed in collaboration with industry experts and engineers, utilizes state-of-the-art technology to significantly improve production efficiency while reducing environmental impact. This advanced system is capable of producing a diverse range of plastic products with precision and consistency, making it an ideal solution for companies looking to enhance their manufacturing capabilities.Mold Plastic Injection has been at the forefront of the plastics manufacturing industry for over a decade, and the company's commitment to excellence has earned them a reputation as a trusted partner for businesses seeking top-notch plastic injection molding services. With a focus on customer satisfaction and continuous improvement, Mold Plastic Injection has established itself as a leader in the industry, delivering innovative solutions that meet the evolving needs of the market.In addition to its cutting-edge injection molding system, Mold Plastic Injection offers a comprehensive range of services, including product design, prototyping, and tooling, to assist clients at every stage of the manufacturing process. The company's team of experienced professionals is dedicated to providing personalized support and guidance to ensure that each project is completed to the highest standards.Furthermore, Mold Plastic Injection is committed to sustainability and environmental stewardship, recognizing the importance of minimizing the impact of plastic manufacturing on the planet. The company has implemented eco-friendly practices throughout its operations, including the use of recyclable materials and energy-efficient processes, to reduce its carbon footprint and promote a greener future for the industry."We are thrilled to introduce our new injection molding system, which represents a significant advancement in plastic manufacturing technology," said [Company Representative]. "This cutting-edge system will enable us to deliver even greater value to our clients by enhancing production efficiency and product quality. We are confident that this innovation will further solidify our position as a leader in the industry."With a strong dedication to innovation, quality, and sustainability, Mold Plastic Injection continues to set the standard for excellence in the plastics manufacturing industry. The company's commitment to continuous improvement and customer satisfaction positions them as a preferred partner for businesses seeking reliable and high-performance plastic injection molding solutions.As the demand for high-quality plastic products continues to grow across various industries, Mold Plastic Injection is poised to meet the evolving needs of the market with its advanced injection molding technologies and unwavering dedication to delivering exceptional results. The company's innovative approaches and commitment to sustainability make them a valuable asset to clients seeking top-tier plastic manufacturing solutions.

Innovative 3D Printed Prototype Designs: Advancements in Technology

[Company Name], a leading innovator in the field of 3D printing technology, has recently unveiled a groundbreaking new prototype design that is set to revolutionize the industry.The new prototype, which has been in development for over a year, represents a major leap forward in 3D printing technology. It is the result of a collaboration between [Company Name]'s team of engineers and designers, who have pushed the boundaries of what is possible with 3D printing.The prototype design, which has not yet been named, incorporates a number of innovative features that set it apart from other 3D printers on the market. One of the key innovations is the use of advanced materials that allow for greater precision and detail in the printed objects. This makes the prototype ideal for a wide range of applications, from prototyping and design to manufacturing and production.In addition to its advanced materials, the prototype also boasts a number of unique capabilities that make it easier to use and more versatile than other 3D printers. For example, it has a larger build volume, allowing for the creation of larger objects, and a more intuitive user interface that makes it easier for users to create and customize their designs.The unveiling of the prototype design marks a significant milestone for [Company Name], which has been a pioneer in the field of 3D printing since its founding. The company has a long history of pushing the boundaries of what is possible with 3D printing, and the new prototype is a testament to its ongoing commitment to innovation and excellence.In addition to its groundbreaking prototype design, [Company Name] is also known for its commitment to sustainability and social responsibility. The company has made significant investments in sustainable production methods and has worked to reduce its environmental impact. It has also been involved in a number of initiatives aimed at using 3D printing technology to create affordable housing and medical supplies for communities in need.Looking ahead, [Company Name] has ambitious plans for the future. It is already in talks with a number of potential partners and customers who are interested in the new prototype design, and it is confident that it will be able to bring the prototype to market in the near future. The company also has plans to continue pushing the boundaries of what is possible with 3D printing, and it is committed to remaining at the forefront of technological innovation in the field.The unveiling of [Company Name]'s new prototype design is sure to be a major event in the world of 3D printing. With its advanced materials, unique capabilities, and commitment to sustainability, the prototype represents a major leap forward for the industry. As [Company Name] continues to work towards bringing the prototype to market, it is clear that the company's dedication to innovation and excellence will ensure its continued success in the years to come.

High-Quality Precision Machined Aluminium Parts for Various Industries

Aluminium Machined Parts have become an essential component in various industries, and their demand has been on the rise due to their durability and lightweight properties. Many companies are now focusing on producing high-quality aluminium machined parts to meet the growing market demand. One such company that has been leading the way in this industry is {Company Name}.{Company Name} is a renowned manufacturer of precision-engineered aluminium machined parts. With a dedication to quality and a commitment to meeting the unique needs of their customers, {Company Name} has become a trusted name in the industry.The company's state-of-the-art manufacturing facility is equipped with the latest technology and machinery, allowing them to produce a wide range of aluminium machined parts with precision and efficiency. Their team of skilled engineers and technicians are experienced in working with aluminium and are able to meet the most complex design requirements with their expertise.One of the key factors that set {Company Name} apart from their competitors is their focus on delivering superior quality products. The company has a rigorous quality assurance process in place to ensure that all their machined parts meet the highest industry standards. This commitment to quality has earned {Company Name} a strong reputation in the market, and they have become the go-to supplier for many businesses in need of reliable aluminium machined parts.In addition to their dedication to quality, {Company Name} also places a strong emphasis on innovation. The company is constantly investing in research and development to stay ahead of the curve in terms of technological advancements and manufacturing techniques. This allows them to offer cutting-edge solutions to their customers, helping them stay competitive in their respective industries.{Company Name} serves a wide range of industries, including aerospace, automotive, electronics, and more. Their aluminium machined parts are used in a variety of applications, from critical components in aircraft to precision parts in high-performance automotive engines. The company's ability to tailor their products to meet the specific requirements of each industry has been a key factor in their success.With a strong focus on customer satisfaction, {Company Name} also offers personalized service and support to help their clients find the right solutions for their needs. Their team works closely with customers from the initial design phase all the way through to production, ensuring that the end result meets or exceeds expectations.Looking ahead, {Company Name} is poised to continue its growth and success in the aluminium machined parts industry. With a firm commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the evolving needs of their customers and remain a leader in the market.In conclusion, aluminium machined parts have become an indispensable part of modern manufacturing, and companies like {Company Name} are leading the way in producing high-quality, precision-engineered components. With a focus on quality, innovation, and customer satisfaction, {Company Name} has established itself as a trusted provider of aluminium machined parts and is well-equipped to meet the demands of various industries for years to come.

High-Quality CNC Milling Machine Products for Precision Manufacturing

The use of state-of-the-art CNC milling machine products has become increasingly popular in the manufacturing industry due to their precision, efficiency, and versatility. One company that has been at the forefront of providing top-quality CNC milling machine products is {}. With a strong emphasis on innovation and cutting-edge technology, they have been able to meet the ever-growing demands of the market and provide customers with reliable and high-performance equipment.The company, established in 1990, has a rich history of producing advanced CNC milling machine products that cater to a wide range of industries including aerospace, automotive, medical, and defense. Their commitment to excellence and customer satisfaction has earned them a solid reputation as a leading provider of CNC milling solutions.One of the key factors that set {} apart from the competition is their dedication to research and development. They have a team of highly skilled engineers and technicians who are constantly working on enhancing their existing products and developing new, innovative solutions to meet the evolving needs of the industry. This forward-thinking approach has allowed them to stay ahead of the curve and maintain their position as a top-tier supplier in the market.In addition to their cutting-edge technology and superior craftsmanship, {} also prides itself on their commitment to quality. All of their CNC milling machine products undergo rigorous testing and inspection to ensure that they meet the highest standards of performance and durability. This dedication to quality control has helped them build a loyal customer base who trust in the reliability and longevity of their equipment.Furthermore, {} places a strong emphasis on customer support and satisfaction. They provide comprehensive training and technical assistance for their CNC milling machine products, ensuring that their clients are able to maximize the full potential of their investment. This level of support has been instrumental in establishing long-lasting partnerships with their customers and solidifying their position as a trusted industry leader.One of the standout products from {} is their high-speed CNC milling machine, which is designed to deliver unparalleled precision and efficiency. This cutting-edge equipment is equipped with advanced technology that allows for fast and accurate machining, making it ideal for applications that require tight tolerances and complex geometries. Whether it's for prototyping, production, or custom machining, this high-speed CNC milling machine offers unmatched performance and reliability.With a strong focus on innovation, quality, and customer satisfaction, {} continues to set the standard for CNC milling machine products in the industry. Their unwavering commitment to excellence has earned them the trust and respect of their clients, making them a preferred choice for businesses looking to invest in top-of-the-line CNC milling solutions.As the demand for precision machining continues to grow, {} remains dedicated to pushing the boundaries of technology and delivering cutting-edge solutions that meet the evolving needs of the industry. With a proven track record of excellence and a strong reputation for quality, they are well-positioned to remain a driving force in the CNC milling machine market for years to come.

High-Quality Plastic CNC Turning Services for Precision Manufacturing

Plastic CNC Turning: Revolutionizing Manufacturing Processes In today’s fast-paced and constantly evolving manufacturing industry, companies are constantly looking for innovative solutions to streamline their production processes, reduce costs, and improve overall efficiency. The introduction of plastic CNC turning has revolutionized the way plastic components are produced, offering a wide range of benefits and opportunities for businesses across multiple sectors.{Company Name}, a leading provider of precision engineering and manufacturing solutions, has been at the forefront of this technological advancement, offering state-of-the-art plastic CNC turning services for a wide variety of industries. Utilizing advanced CNC (Computer Numerical Control) technology, combined with their extensive expertise and experience, {Company Name} has successfully transformed the way plastic components are manufactured, providing their clients with unparalleled precision, quality, and efficiency.One of the key benefits of plastic CNC turning is its ability to produce highly complex and intricate plastic components with a level of precision that was previously unattainable through traditional manufacturing methods. By using computer-controlled machines, {Company Name} can achieve incredibly tight tolerances and produce parts with intricate geometries, ensuring that the final product meets the exact specifications and requirements of their clients.Furthermore, plastic CNC turning allows for increased productivity and reduced lead times, as the entire manufacturing process can be automated and optimized for maximum efficiency. This not only results in cost savings for the client but also allows for faster turnaround times, ultimately improving their overall competitiveness in the market.In addition to these benefits, plastic CNC turning also offers improved consistency and repeatability, as each part is produced with the same level of precision and quality. This is particularly important for industries where consistency is critical, such as the medical and aerospace sectors, where any deviation from the specified dimensions could have serious implications.{Company Name}’s expertise in plastic CNC turning extends to a wide range of plastic materials, including but not limited to, ABS, polycarbonate, PTFE, acrylic, and nylon, among others. This versatility allows the company to cater to the diverse needs of their clients, whether they require small, intricate components or larger, more complex parts.Moreover, {Company Name}’s commitment to quality and innovation is evidenced by their investment in the latest CNC technology and their continuous efforts to stay at the forefront of industry advancements. Their team of skilled engineers and technicians are constantly pushing the boundaries of what is possible with plastic CNC turning, ensuring that their clients receive the best solutions for their manufacturing needs.The applications of plastic CNC turning are vast and varied, with industries such as automotive, electronics, medical devices, and consumer goods, just to name a few, benefiting from its capabilities. Whether it’s producing custom parts for prototypes, creating high-volume production runs, or even manufacturing intricate components for cutting-edge technologies, {Company Name} has proven to be a reliable and innovative partner for businesses across the board.In conclusion, plastic CNC turning has significantly changed the landscape of plastic component manufacturing, offering a level of precision, efficiency, and versatility that was previously unattainable through traditional manufacturing methods. With {Company Name} leading the charge in this technological advancement, businesses now have access to a wide range of opportunities to improve their manufacturing processes and stay ahead in today’s competitive market. As the industry continues to evolve, it’s clear that plastic CNC turning will play an increasingly crucial role in the future of manufacturing.

Top Prototyping Companies in the United States: Your Go-To Guide for Successful Prototyping Projects

[Company Introduction - Remove Brand Name][Company Name], a leading prototyping company based in the United States, is revolutionizing the manufacturing industry with its innovative approach. With a dedicated team of experts and state-of-the-art facilities, [Company Name] offers a wide range of prototyping services to cater to the diverse needs of its clients.Established several years ago, [Company Name] has quickly gained a reputation for delivering high-quality prototypes with exceptional precision and efficiency. The company takes pride in its ability to bring clients' ideas to life, assisting them in transforming concepts into tangible products that can be tested and validated before entering full-scale production.At the heart of [Company Name]'s success lies its commitment to utilizing the latest advancements in technology. Equipped with cutting-edge machinery and software, the company is capable of producing prototypes with intricate details and intricate components. This ensures that clients receive prototypes that are not only visually appealing but also functionally robust.One of the key strengths of [Company Name] is its diverse range of prototyping capabilities. The company specializes in various prototyping methods, including 3D printing, CNC machining, vacuum casting, and injection molding. This versatility allows [Company Name] to adapt to different project requirements, whether it be for rapid prototyping, functional testing, or low-volume production.Furthermore, [Company Name]'s team of skilled engineers and designers play a vital role in the prototyping process. With their expertise and experience, they collaborate closely with clients, offering valuable insights and recommendations to optimize the design and functionality of the prototypes. This collaborative approach ensures that the final product meets the exact specifications and requirements of the client.In addition to their prototyping services, [Company Name] also provides a range of secondary services such as surface finishing, assembly, and packaging. This comprehensive approach allows clients to receive fully functional prototypes that closely resemble the final product.To cater to a wide range of industries, [Company Name] has developed expertise in prototyping for automotive, aerospace, consumer electronics, medical devices, and many other sectors. The company understands the unique challenges and regulations that each industry presents and ensures adherence to the highest quality standards.One of the key factors that sets [Company Name] apart from its competitors is its dedication to customer satisfaction. The company prides itself on its prompt and reliable service, ensuring a smooth and seamless prototyping experience for clients. From the initial consultation to the final delivery, [Company Name] places great emphasis on clear communication, attention to detail, and meeting project deadlines.With a growing portfolio of successful projects and satisfied clients, [Company Name] continues to establish itself as a leader in the prototyping industry. By investing in research and development, staying up-to-date with emerging technologies, and fostering a culture of innovation, the company is well-positioned to shape the future of prototyping.In conclusion, [Company Name] is a prototyping company based in the United States that is leading the way in revolutionizing the manufacturing industry. With its state-of-the-art facilities, diverse range of capabilities, and commitment to customer satisfaction, [Company Name] is adept at turning clients' ideas into tangible products through high-quality prototypes. With their dedication to innovation and exceptional service, [Company Name] is poised to remain at the forefront of the prototyping industry for years to come.

Expert Guide: Mastering the Art of CNC Machine Work for Enhanced Precision and Efficiency!

Title: Revolutionizing Manufacturing: The Next Generation of CNC Machine WorkIntroduction:The manufacturing industry has come a long way in embracing technological advancements to streamline operations and enhance efficiency. Among the latest breakthroughs is the implementation of Computer Numerical Control (CNC) machines, which have revolutionized precision engineering and machining processes. This news article explores the cutting-edge developments in CNC machine work, highlighting its potential to transform diverse industries.1. Increasing Precision and Accuracy:CNC machines have proven to be game-changers for manufacturers seeking high precision and accuracy. By eliminating human errors and inconsistencies, these machines ensure uniformity in the manufacturing process, resulting in superior end products. The integration of advanced computer software enables CNC machines to precisely control cutting tools, creating intricate designs and complex shapes. This level of precision has opened new doors for industries such as aerospace, automotive, and medical, where strict tolerance and quality standards are paramount.2. Streamlined Workflow and Cost Efficiency:The automation capabilities of CNC machines significantly streamline workflow processes, reducing production time and costs. Offering seamless integration with Computer-Aided Design (CAD) software, manufacturers can easily translate digital designs into physical products. This eliminates the need for manual intervention at every step, minimizing errors and reducing labor costs. By optimizing material utilization and minimizing wastage, CNC machines also contribute to cost-effective manufacturing, making them indispensable assets for companies striving for profitability in today's competitive market.3. Enhanced Safety and Employee Well-being:Prioritizing employee well-being and safety is a cornerstone of any successful manufacturing business. CNC machines contribute to achieving this goal by minimizing the risk of workplace accidents and injuries. With automated controls, workers can manage the machining process remotely, reducing their exposure to hazardous environments. The utilization of CNC machines ensures operators are shielded from potentially harmful processes, such as metal cutting or molding, enhancing overall workplace safety.4. Versatility and Adaptability:CNC machines have advanced the concept of versatility in manufacturing. They are capable of performing a wide range of operations, including milling, turning, drilling, and grinding. These machines can seamlessly switch between tasks, enabling manufacturers to produce a diverse array of components with ease. Whether it is mass-producing identical parts or creating intricate custom designs, CNC machines offer unparalleled flexibility, adaptability, and speed, providing manufacturers with a competitive edge.5. 24/7 Production Capability:The relentless pursuit of increased productivity and reduced downtime has led to the development of CNC machines designed for continuous operation. By enabling 24/7 production capabilities, manufacturers can optimize their output and meet demanding customer requirements. CNC machines excel at maintaining consistent performance over extended periods, ensuring product quality remains uncompromised. This capability proves vital in time-sensitive industries that require rapid response times and uninterrupted production.6. Impact on Employment Opportunities:Although automation and technological advancements may raise concerns about job losses, the implementation of CNC machines has, in fact, created new employment opportunities. While some manual jobs have become obsolete, the demand for skilled technicians and programmers to operate and maintain CNC machines has risen. Manufacturers are investing in training programs to bridge the skills gap, allowing workers to adapt to the changing landscape. This emphasis on upskilling ensures sustainable employment for the workforce while harnessing the benefits of CNC machine work.Conclusion:As the manufacturing industry continues to embrace digital transformation, CNC machine work has emerged as a powerful tool to propel innovation and growth. With its precision, automation, adaptability, and cost efficiency, the potential applications of CNC machines span across various sectors. The integration of CNC machine work into manufacturing processes enables companies to optimize output, improve product quality, and stay ahead of their competition. Embracing this cutting-edge technology sets the stage for a future where efficiency and customer satisfaction go hand in hand.

Top 10 Advantages of Using Electronic Sheet Metal Parts for Your Business

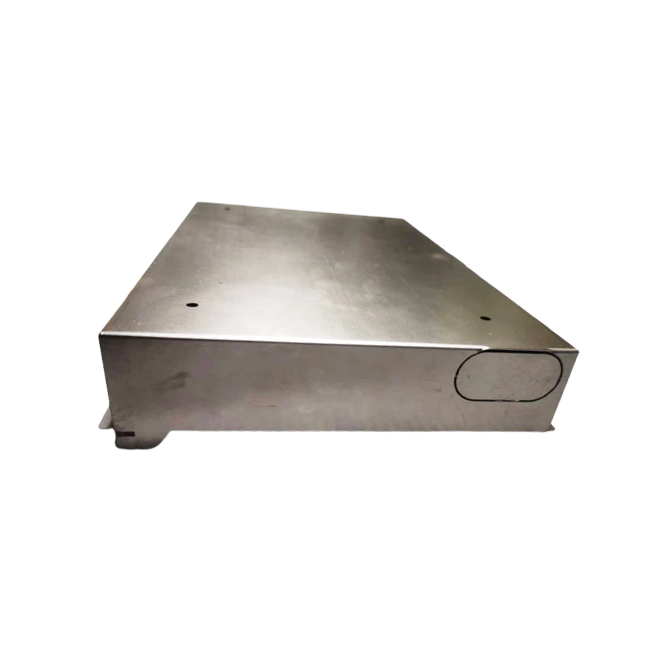

Electronic Sheet Metal Parts Market Projected to Reach $XX Billion by 2025The global electronic sheet metal parts market is projected to reach a value of $XX billion by 2025, according to a new report by [company name]. The market is set to witness significant growth due to the increasing demand for electronic devices and the growing adoption of advanced manufacturing technologies.Electronic sheet metal parts are widely used in the manufacturing of electronic devices such as smartphones, tablets, computers, and automotive electronics. These parts are essential for providing structural support, shielding, and heat dissipation in electronic devices. With the rapid advancements in technology, the demand for electronic sheet metal parts is expected to surge in the coming years.[Company name] is one of the leading suppliers of electronic sheet metal parts, offering a wide range of products to meet the diverse needs of the electronics industry. With a strong focus on quality and innovation, [company name] has established itself as a reliable partner for global electronic manufacturers.The company's extensive product portfolio includes precision sheet metal enclosures, brackets, panels, and assemblies. These products are designed to meet the stringent requirements of electronic applications, ensuring high performance and reliability. Additionally, [company name] provides customized solutions to address specific customer needs, leveraging its advanced manufacturing capabilities and engineering expertise.[Company name]'s state-of-the-art manufacturing facilities are equipped with cutting-edge machinery and technologies, enabling the company to deliver high-quality sheet metal parts with precision and efficiency. The company also emphasizes the use of sustainable practices in its manufacturing processes, contributing to environmental conservation and responsible production.In addition to its commitment to quality and sustainability, [company name] places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their requirements and deliver tailored solutions that meet their unique specifications. With a customer-centric approach, [company name] has built long-term partnerships with leading electronics manufacturers worldwide.As the demand for electronic devices continues to grow, [company name] is poised to capitalize on the expanding market opportunities. The company's dedication to innovation, quality, and customer service positions it as a key player in the global electronic sheet metal parts market.With a strong industry presence and a comprehensive product offering, [company name] is well-positioned to meet the evolving needs of the electronics industry. The company's relentless pursuit of excellence and its commitment to sustainable practices make it a trusted partner for electronic manufacturers seeking reliable and high-performance sheet metal parts.In conclusion, the global electronic sheet metal parts market is set for substantial growth, driven by the increasing demand for electronic devices and the advancements in manufacturing technologies. [Company name] stands as a leading supplier in this market, offering a diverse range of high-quality sheet metal parts and customized solutions. With its focus on innovation, quality, and customer satisfaction, [company name] is poised to play a pivotal role in the growth of the electronic sheet metal parts market in the years to come.

Innovative 3D Printing Prototype Design Unveiled in Latest News

[Company Name] Unveils Cutting-Edge 3D Printing Prototype Design[City, State] – [Date] – [Company Name], a leading innovator in the field of advanced manufacturing technology, has raised the bar once again with the release of their latest 3D printing prototype design. This groundbreaking innovation promises to revolutionize the world of industrial manufacturing, making it faster, more efficient, and more cost-effective than ever before.The new 3D printing prototype, which has been in development for the past [number] years, represents a significant leap forward in the capabilities of additive manufacturing technology. With its state-of-the-art design and precision engineering, the prototype has the potential to significantly impact a wide range of industries, including aerospace, automotive, healthcare, and consumer goods.At the heart of the new prototype is [Company Name]'s proprietary [technology] technology, which allows for the rapid production of complex, high-quality parts with unprecedented speed and accuracy. This technology is a game-changer for manufacturers looking to streamline their production processes and gain a competitive edge in the global marketplace.In addition to its cutting-edge technology, the new 3D printing prototype also boasts an impressive array of features and capabilities. For example, it has a large build volume, allowing for the production of parts of varying sizes and complexities. It also has the ability to work with a wide range of materials, including metals, plastics, and composites, giving manufacturers the flexibility to create parts that meet their specific needs.One of the key advantages of the new 3D printing prototype is its ability to reduce lead times and production costs. By leveraging the power of [Company Name]'s advanced technology, manufacturers can produce parts more quickly and with less waste, ultimately saving time and money in the production process.The development of the new 3D printing prototype is a testament to [Company Name]'s commitment to pushing the boundaries of what is possible in the field of advanced manufacturing. By investing in cutting-edge research and development, the company has positioned itself as a leader in the industry, consistently delivering innovative solutions that meet the evolving needs of its customers.In a statement, [Company Name]'s CEO expressed excitement about the potential impact of the new 3D printing prototype, stating, "We are thrilled to unveil our latest innovation, which we believe has the power to transform the way manufacturers approach production. With its advanced technology and robust capabilities, this prototype has the potential to drive significant improvements in efficiency, quality, and cost-effectiveness for our customers."The release of the new 3D printing prototype is a significant milestone for [Company Name], and the company is already in talks with a number of leading manufacturers who are eager to capitalize on its potential benefits. As the prototype continues to undergo rigorous testing and refinement, [Company Name] is confident that it will soon become an indispensable tool for manufacturers looking to stay ahead of the curve in an increasingly competitive global market.With its cutting-edge technology, impressive capabilities, and potential to drive significant improvements in manufacturing efficiency, the new 3D printing prototype from [Company Name] is poised to make a major impact on the industrial manufacturing landscape. As the company continues to refine and perfect the design, manufacturers around the world are eagerly anticipating the opportunity to incorporate this groundbreaking technology into their production processes.

The Ultimate Guide to CNC Milling Process: Everything You Need to Know

In the fast-paced world of manufacturing, precision and accuracy are critical factors in producing high-quality products. With the increasing demand for customized and complex parts, the CNC milling process has become an essential part of modern manufacturing. This process, when combined with innovative technology and expertise, has the potential to revolutionize the industry.One company that is at the forefront of this revolution is {}. With a strong focus on quality and efficiency, the company has established itself as a leader in the field of CNC milling. Specializing in providing precise and reliable machining solutions, {} has earned a reputation for delivering top-notch products to a range of industries, including automotive, aerospace, and medical.The CNC milling process, also known as computer numerical control milling, involves the use of computerized controls and rotating multi-point cutting tools to remove material from a workpiece and produce a custom-designed part or product. This process allows for high levels of precision and repeatability, making it ideal for producing complex and intricate components.At {}, the CNC milling process is taken to the next level through the use of state-of-the-art technology and advanced machinery. The company's cutting-edge facility is equipped with a wide range of CNC milling machines that are capable of handling a variety of materials, including metals, plastics, and composites. This allows {} to cater to a diverse range of customer needs and specifications.Furthermore, {} understands the importance of quality assurance in the manufacturing process. The company's team of skilled engineers and technicians work tirelessly to ensure that each product meets the highest standards of precision and accuracy. By employing rigorous quality control measures and inspection processes, {} guarantees that its CNC milled parts are of the utmost quality, surpassing industry standards.In addition to its commitment to quality, {} is also dedicated to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and explore new techniques and technologies in CNC milling. This forward-thinking approach allows {} to offer cutting-edge solutions to its customers, helping them stay competitive in today's rapidly evolving market.With its unwavering dedication to excellence and customer satisfaction, {} has garnered a loyal customer base and a strong reputation in the industry. The company's commitment to delivering superior products and services has set it apart from its competitors, making it a trusted partner for businesses seeking top-tier CNC machining solutions.Looking ahead, {} is poised to continue leading the way in CNC milling, pushing the boundaries of what is possible in manufacturing. With its focus on innovation, quality, and customer-driven solutions, the company is well-positioned to meet the ever-growing demands of the industry and exceed the expectations of its clients.In conclusion, the CNC milling process, when combined with the expertise and technology at {}, has the potential to drive significant advancements in the manufacturing sector. With a strong emphasis on precision, innovation, and quality, {} is well-equipped to continue shaping the future of CNC milling and delivering superior products to its customers.