- Home

- Basic Components Of Cnc System

Basic Components of CNC System: Explained by a Leading Manufacturer

Introducing the latest innovation in CNC technology, brought to you by Guangdong Shunde Teamwork Model Co., Ltd., a leading manufacturer, supplier, and factory in China. Our state-of-the-art CNC system combines precision, efficiency, and reliability to revolutionize the manufacturing industry.

Designed with the utmost attention to detail, our CNC system comprises the basic components necessary for seamless operation. With cutting-edge technology and advanced software, it delivers unparalleled accuracy and speed, ensuring consistent and flawless results.

Our CNC system is equipped with a powerful controller that acts as the brain, coordinating and synchronizing the various components. The high-resolution display provides comprehensive control and monitoring, allowing operators to optimize production processes. The robust servo motors ensure smooth and precise movement, while the durable ball screws guarantee exceptional stability and repeatability.

With our CNC system, manufacturers can streamline their operations, increase productivity, and reduce downtime. Whether you are producing intricate parts or large-scale components, our system will exceed your expectations.

Choose Guangdong Shunde Teamwork Model Co., Ltd. for a reliable, efficient, and innovative CNC system that will elevate your manufacturing capabilities to new heights. Contact us today to learn more about our cutting-edge products.

Guangdong Shunde Teamwork Model Technology Co., Ltd.

Company News

Related News

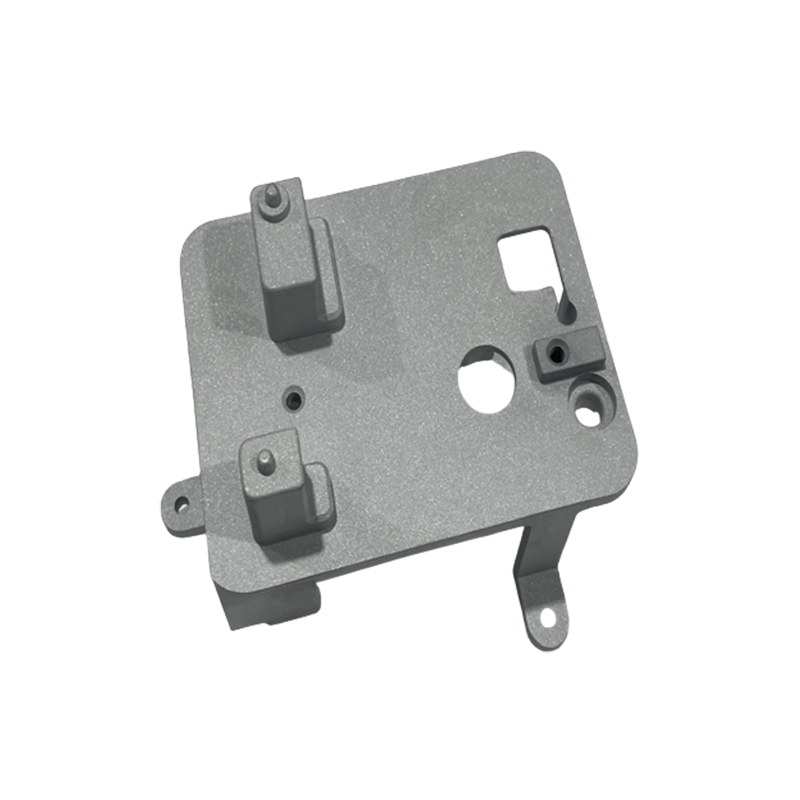

Professional CNC Machining Aluminum Anodized Spare Parts Prototype

Get top-quality CNC machined aluminum anodized spare parts prototypes from our factory. Exceptional precision and durability for diverse industries. Order now!

Custom precision CNC machining brass part service manufacturer

Looking for a reliable precision CNC machining brass part manufacturer? Our factory offers custom services with high-quality products. Visit us today!

OEM 3D Printing Rapid prototyping SLA SLS Printing Service Manufacturer in China

Leading OEM 3D Printing Service Manufacturer in China. Utilize SLA & SLS Technologies for Rapid Prototyping. Factory-direct quality at competitive prices.

High Precision Aluminum CNC Machining Components Prototyping

Get high precision aluminum CNC machining components prototyping done at our factory. We specialize in delivering top-notch products with utmost precision and efficiency. Contact us now!

Custom automotive sheet metal/metal prototype parts

Introducing our factory-made CustomMetalPro automotive sheet metal prototype parts. We deliver top-quality products with precision and expertise. Order now for the best results!

OEM Service CNC Aluminum Machining Parts Sandblasting Prototyping

Get superior OEM service for CNC aluminum machining parts sandblasting prototyping. We are a leading factory offering high-quality products.

OEM Customized 3D Printing Metal Parts Aluminum Rapid Prototyping Service

Get precision OEM customized 3D printing metal parts & aluminum rapid prototyping service from our factory. Explore our high-quality products today!

OEM Manufacturing Automotive Parts Precision CNC Aluminum Machining Parts

Shop high-quality OEM automotive parts at our precision CNC aluminum machining factory. Get reliable and precise products for your vehicles. Browse now!

OEM cnc sheet metal bending laser cutting service manufacturer

Looking for reliable OEM CNC sheet metal bending and laser cutting services? Look no further! Our factory is a leading manufacturer you can trust.

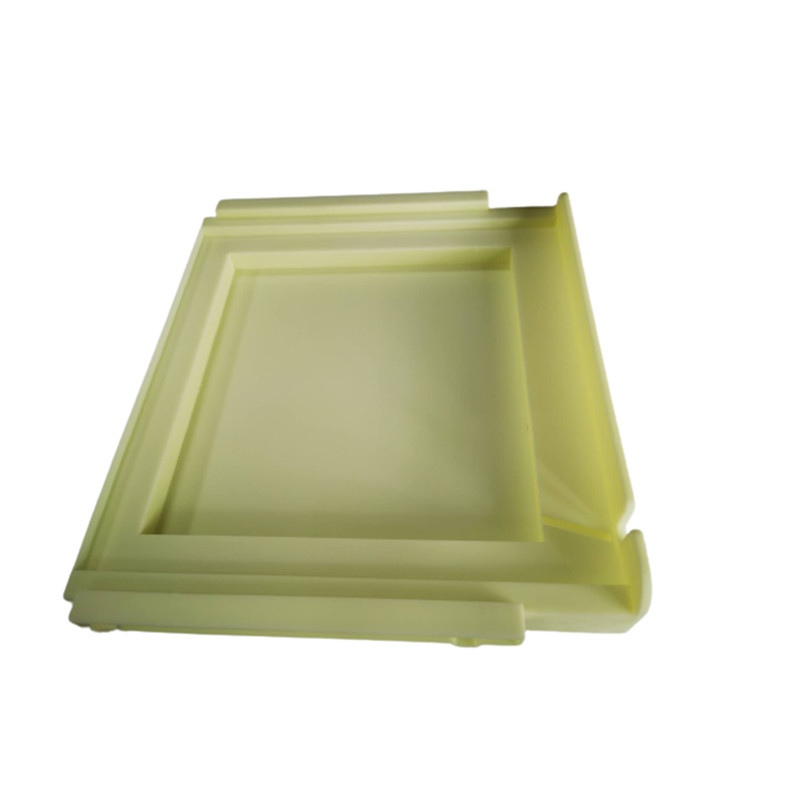

Fabrication CNC Machining Rapid Prototype ABS Plastic Parts Factory

Looking for high-quality ABS plastic parts? Look no further! Our Fabrication CNC Machining Rapid Prototype Factory is your trusted source. Contact us now!

Customized high-quality 3D printing plastic service Chinese prototype factory

Get exceptional quality 3D printed plastic prototypes from our Chinese factory. We offer customized services tailored to meet your unique needs. Contact us today.

Customized 3D Printing ABS Plastic Parts SLA Printing Rapid Prototype

Get high-quality customized 3D printing ABS plastic parts through SLA printing. We are a factory specializing in rapid prototyping. Order now!

Customized metal parts stainless steel part stretching&spinning factory OEM service

Get top-notch customized metal parts with our stainless steel stretching and spinning factory. We provide OEM services, guaranteeing unrivaled quality. Contact us now!

New High Preformance 3D Printing SLS PLA Nylon Model Sample Prototype

Introducing our factory's exclusive New High Performance 3D Printing SLS PLA Nylon Model Sample Prototype. Get top-quality, innovative 3D printing solutions.

OEM component metal machining parts CNC aluminium factory service

Looking for high-quality OEM component metal machining parts? Our CNC aluminium factory offers top-notch services. Contact us today for factory-direct pricing and excellent customer service.

- Basic Components of CNC System: Explained by a Leading Manufacturer

- Reviews

- Related Videos

Introducing the revolutionary CNC System, designed to empower the manufacturing industry with speed, precision, and efficiency. Our state-of-the-art system incorporates the basic components of CNC technology, ensuring unparalleled performance for businesses of all sizes. At the heart of our product lies the computer, which acts as the control unit and manages the entire manufacturing process. With advanced programming capabilities, it translates complex designs into instructions that drive the CNC machine. The machine itself is equipped with servo motors that precisely control the tool movements, grip materials, and perform intricate operations with minimal human intervention. The CNC System also features an array of sensors and feedback devices, ensuring high accuracy and error detection. These components work together seamlessly to maintain optimal performance and enhance productivity, reducing downtime and waste. Coupled with our user-friendly software interface, operators can easily program, monitor, and troubleshoot the system, saving valuable time and resources. Versatility is another key characteristic of our CNC System. It accommodates a wide range of materials and can execute a diverse set of operations, including cutting, drilling, milling, and engraving. Whether you are in the automotive, aerospace, or consumer goods industry, our system is designed to meet your unique manufacturing needs. Furthermore, our CNC System is built to last. With robust hardware and rigorous quality control measures, it ensures long-term reliability and durability. Backed by our extensive technical support, we guarantee a seamless integration process and provide ongoing assistance to maximize your productivity. Join the league of industry pioneers who have embraced the power of CNC technology. Upgrade to our CNC System today and experience a new level of precision, efficiency, and profitability for your business. Get ready to revolutionize your manufacturing processes and stay ahead in the competitive market.

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours