Discover the Top Metal Fabrication Services for Customized Solutions

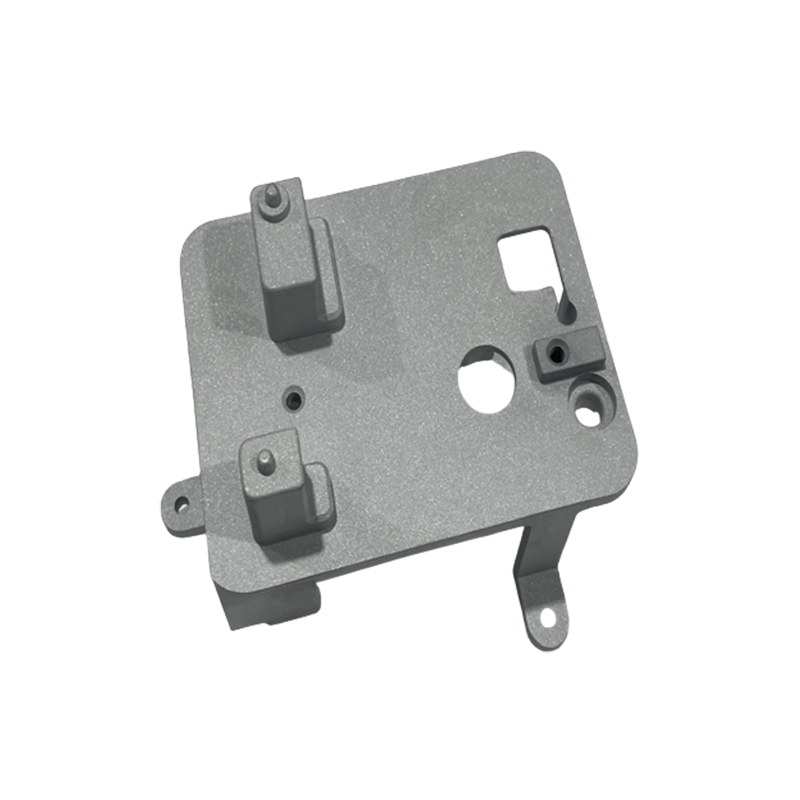

Custom Metal Fabrication Company Introduces Innovative Solutions for Industries[City, State] - [Date]Custom Metal Fabrication, a leading provider of metal fabrication services, is revolutionizing the industry with its innovative solutions tailored to meet the specific needs of various industries. The company is known for its commitment to precision, quality, and on-time delivery, making it the go-to choice for businesses that require custom metal fabrication services.Custom Metal Fabrication has established itself as a trusted partner for industries such as aerospace, automotive, construction, energy, and more. With state-of-the-art facilities and a team of highly skilled professionals, the company excels in delivering exceptional metal fabrication solutions that exceed customer expectations.The company offers a wide range of metal fabrication services, including laser cutting, bending, welding, machining, assembly, and finishing. Their advanced equipment and technologies enable them to work with a variety of metals, such as stainless steel, aluminum, carbon steel, and more. Custom Metal Fabrication's attention to detail ensures that every project is handled with precision and meets the highest industry standards.One of the key features that sets Custom Metal Fabrication apart from its competitors is its ability to provide customized solutions. The company's experienced engineers and designers collaborate closely with clients to understand their unique requirements and develop tailored solutions to address their specific challenges. Whether it's a one-off prototype or a large-scale production run, Custom Metal Fabrication has the expertise and resources to deliver top-quality results.In addition to its commitment to customization, the company also places a strong emphasis on innovation. With an in-house research and development team, Custom Metal Fabrication constantly explores new techniques and technologies to enhance their fabrication processes and stay ahead of industry trends. This dedication to innovation ensures that their clients benefit from the latest advancements in metal fabrication, allowing them to improve efficiency, reduce costs, and maintain a competitive edge.One of the notable innovations introduced by Custom Metal Fabrication is its adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies. This enables the company to streamline its workflow, minimize errors, and optimize production schedules. By leveraging these advanced tools, Custom Metal Fabrication improves accuracy, accelerates production, and ensures consistent quality throughout the manufacturing process.Furthermore, Custom Metal Fabrication also prioritizes environmental sustainability. The company understands the importance of reducing its environmental footprint, and as such, implements eco-friendly practices throughout its operations. From using energy-efficient equipment to recycling and properly disposing of materials, Custom Metal Fabrication is committed to minimizing its impact on the environment.The company's dedication to delivering exceptional products and services has earned them a stellar reputation in the industry. Numerous satisfied clients have praised Custom Metal Fabrication for their professionalism, reliability, and the ability to deliver projects on time and within budget.Custom Metal Fabrication's commitment to innovation, customization, and sustainability positions them as a leader in the metal fabrication industry. With their state-of-the-art facilities, experienced team, and a track record of delivering high-quality results, the company continues to be the preferred choice for businesses seeking custom metal fabrication solutions.For more information about Custom Metal Fabrication and its services, please visit [website].About Custom Metal Fabrication:Custom Metal Fabrication is a leading provider of metal fabrication services, specializing in precision, quality, and on-time delivery. With its innovative solutions tailored to meet the specific needs of various industries, the company has established itself as a trusted partner for businesses in aerospace, automotive, construction, energy, and more. Custom Metal Fabrication is dedicated to providing exceptional products and services, leveraging advanced technologies, and practicing environmental sustainability.

Read More

CNC Lathe Machining: The Ultimate Guide for Precision Turning

CNC Lathe Machining Revolutionizes Manufacturing IndustryIn a world driven by technological advancements, precision and efficiency have become the cornerstone of manufacturing processes. One such significant innovation that has transformed the industry in recent years is CNC lathe machining. Removing the brand name, we take a closer look at this groundbreaking technology that has revolutionized the manufacturing sector.CNC lathe machining, also known as computer numerical control lathe machining, is a manufacturing process that utilizes computerized controls and automated systems to produce intricate and precise parts. This highly advanced technique has completely transformed traditional turning processes, offering a range of benefits that have propelled companies to adopt this technology.One key advantage of CNC lathe machining is its unparalleled precision. The computerized controls ensure that every component is produced with utmost accuracy, eliminating human errors that may arise in traditional manual operations. This precise machining capability enables manufacturers to produce complex designs and intricate parts that were once impracticable with traditional methods.Speed and efficiency are also significant factors that contribute to the popularity of CNC lathe machining. The automated nature of the process allows for faster production cycles, reducing lead times significantly. Additionally, the computerized controls enable manufacturers to operate multiple machines simultaneously, further improving efficiency and increasing production output.Another noteworthy advantage of CNC lathe machining is its versatility. This technology can be employed to manufacture parts for various industries, including automotive, aerospace, electronics, and medical. From engine components to intricate electronic circuits, CNC lathe machines have proven to be versatile enough to handle diverse manufacturing requirements.The increased automation in CNC lathe machining also leads to improved operational safety. As the need for manual intervention decreases, the risk of accidents and injuries is significantly reduced. This not only ensures the well-being of operators but also results in a safer working environment overall.Furthermore, CNC lathe machining offers enhanced consistency and repeatability. The computerized controls ensure that every part produced adheres to the specified design and dimensional requirements. This consistency is vital in industries where precision and conformity are paramount to product quality.With these advantages in mind, the company {} has emerged as a leading player in the CNC lathe machining market. Established in {}, {} has been at the forefront of innovating and delivering cutting-edge CNC lathe machines to various industries.The company's dedication to research and development has allowed them to push the boundaries of CNC lathe machining technology. By continuously improving their machines, they offer customers advanced features such as high spindle speed, faster tool changing capabilities, and improved automation, resulting in increased productivity and reduced production costs.Moreover, {}'s commitment to customer satisfaction is evident through their comprehensive support services. They provide training and guidance to their clients, ensuring they maximize the potential of the CNC lathe machines. Additionally, their dedicated after-sales service team ensures prompt and effective resolutions to any technical issues that may arise.In recognition of their contributions to the industry, {} has received numerous accolades and certifications for their CNC lathe machines. These achievements further solidify their position as a trusted and reliable provider of CNC lathe machining solutions.As the manufacturing industry continues to embrace automation and precision, CNC lathe machining is set to play an increasingly pivotal role. With its unparalleled accuracy, efficiency, and versatility, companies like {} are leading the charge in revolutionizing the way parts are manufactured. By harnessing the power of CNC lathe machining, businesses can stay competitive in today's fast-paced and evolving market.

Read More

Top 10 Advantages of Using Electronic Sheet Metal Parts for Your Business

Electronic Sheet Metal Parts Market Projected to Reach $XX Billion by 2025The global electronic sheet metal parts market is projected to reach a value of $XX billion by 2025, according to a new report by [company name]. The market is set to witness significant growth due to the increasing demand for electronic devices and the growing adoption of advanced manufacturing technologies.Electronic sheet metal parts are widely used in the manufacturing of electronic devices such as smartphones, tablets, computers, and automotive electronics. These parts are essential for providing structural support, shielding, and heat dissipation in electronic devices. With the rapid advancements in technology, the demand for electronic sheet metal parts is expected to surge in the coming years.[Company name] is one of the leading suppliers of electronic sheet metal parts, offering a wide range of products to meet the diverse needs of the electronics industry. With a strong focus on quality and innovation, [company name] has established itself as a reliable partner for global electronic manufacturers.The company's extensive product portfolio includes precision sheet metal enclosures, brackets, panels, and assemblies. These products are designed to meet the stringent requirements of electronic applications, ensuring high performance and reliability. Additionally, [company name] provides customized solutions to address specific customer needs, leveraging its advanced manufacturing capabilities and engineering expertise.[Company name]'s state-of-the-art manufacturing facilities are equipped with cutting-edge machinery and technologies, enabling the company to deliver high-quality sheet metal parts with precision and efficiency. The company also emphasizes the use of sustainable practices in its manufacturing processes, contributing to environmental conservation and responsible production.In addition to its commitment to quality and sustainability, [company name] places a strong emphasis on customer satisfaction. The company works closely with its customers to understand their requirements and deliver tailored solutions that meet their unique specifications. With a customer-centric approach, [company name] has built long-term partnerships with leading electronics manufacturers worldwide.As the demand for electronic devices continues to grow, [company name] is poised to capitalize on the expanding market opportunities. The company's dedication to innovation, quality, and customer service positions it as a key player in the global electronic sheet metal parts market.With a strong industry presence and a comprehensive product offering, [company name] is well-positioned to meet the evolving needs of the electronics industry. The company's relentless pursuit of excellence and its commitment to sustainable practices make it a trusted partner for electronic manufacturers seeking reliable and high-performance sheet metal parts.In conclusion, the global electronic sheet metal parts market is set for substantial growth, driven by the increasing demand for electronic devices and the advancements in manufacturing technologies. [Company name] stands as a leading supplier in this market, offering a diverse range of high-quality sheet metal parts and customized solutions. With its focus on innovation, quality, and customer satisfaction, [company name] is poised to play a pivotal role in the growth of the electronic sheet metal parts market in the years to come.

Read More

Plastic Fabrication Company Reveals Latest Innovations in [Industry]

[Company Introduction: Please provide the necessary information about the plastic fabrication company, such as its name, location, size, market presence, years of operation, production capabilities, key products/services, target customers, and any unique features or achievements.][Date], [Location] - Plastic fabrication company [Company Name] is revolutionizing the industry by offering innovative solutions for various sectors. With [number] years of experience in the market, the company has positioned itself as a leader in plastic manufacturing and fabrication. By leveraging its cutting-edge technology, skilled workforce, and commitment to excellence, [Company Name] consistently delivers high-quality products and services to its wide array of customers.[Company Name] specializes in the fabrication of a diverse range of plastic products catering to industries such as automotive, aerospace, electronics, medical, packaging, and more. Their state-of-the-art manufacturing facility houses advanced machinery and equipment, enabling them to handle complex projects and high-volume production efficiently. The company's team of experienced engineers and technicians work closely with clients to understand their unique requirements and provide tailored solutions that meet their specific needs.One of the key features that sets [Company Name] apart is their focus on sustainability. As the world is grappling with the consequences of plastic pollution, [Company Name] is committed to minimizing its environmental footprint. They achieve this by implementing eco-friendly manufacturing practices and utilizing recyclable materials wherever feasible. The company aims to promote a circular economy by actively engaging in recycling initiatives and offering environmentally responsible alternatives to traditional plastic products.Furthermore, [Company Name] consistently stays at the forefront of technological advancements in the industry. They invest in research and development to explore new materials, innovative production techniques, and automation to improve product quality, efficiency, and cost-effectiveness. This commitment to innovation has helped [Company Name] secure partnerships with leading companies and establish itself as a trusted supplier in the market.Recently, [Company Name] unveiled their latest breakthrough – [Product/Technology]. This revolutionary technology aims to transform the plastic fabrication industry by [briefly describe the benefits/features of the new product/technology]. The [Product/Technology] has already garnered significant attention within the industry, and early adopters are reaping the benefits of enhanced performance and reduced costs.In addition to its focus on innovation, sustainability, and product excellence, [Company Name] places great emphasis on customer satisfaction. They strive to build long-lasting partnerships with their clients, providing exceptional customer service and continuous support throughout the entire project lifecycle. The company's adherence to stringent quality controls ensures that each product leaving their facility meets the highest industry standards.As [Company Name] continues to grow, they envision expanding their reach into new markets and exploring opportunities for diversification. They plan to leverage their experience and expertise to venture into [industry/sector] and broaden their customer base. This strategic approach, combined with their unwavering commitment to excellence, positions [Company Name] for continued success in the coming years.In conclusion, plastic fabrication company [Company Name] is revolutionizing the industry through its innovative solutions, sustainability initiatives, technological advancements, and commitment to customer satisfaction. With [number] years of experience and a team of skilled professionals, they have established themselves as a leader in the market. Their recent breakthrough, [Product/Technology], showcases their dedication to pushing the boundaries of plastic fabrication and delivering superior products to their clients. With a focus on sustainable practices and a customer-centric approach, [Company Name] is poised for continued growth and success in the ever-evolving plastic fabrication industry.

Read More

The Advantages of Using CNC Technology in Manufacturing

In today's fast-paced manufacturing industry, precision and efficiency are key factors in producing high-quality products. One of the most innovative technologies that have revolutionized manufacturing processes is Computer Numerical Control (CNC). With the integration of CNC machines, companies like {} have been able to streamline their production, increase productivity, and maintain high levels of accuracy in their manufacturing processes.{} has been a leading company in the CNC industry, providing versatile and reliable CNC machines to a wide range of industries. Their commitment to quality and cutting-edge technology has made them a trusted partner for companies looking to enhance their manufacturing capabilities.CNC machines utilize computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control and automate the movement of machining tools such as drills, lathes, and milling machines. This automation allows for precise and complex cutting and shaping of materials such as metal, plastic, and wood, leading to high-quality and consistent products. One of the main benefits of using CNC machines is their ability to produce complex parts with tight tolerances. The precision and repeatability of CNC machining make it an ideal choice for industries such as aerospace, automotive, and medical device manufacturing, where tight tolerances and intricate designs are essential.Furthermore, CNC machines offer increased productivity and efficiency in the manufacturing process. With the ability to run continuously without the need for constant human intervention, CNC machines can produce a high volume of products in a shorter amount of time compared to traditional manual machining methods. This not only reduces production lead times but also lowers labor costs, making CNC machining a cost-effective solution for companies.In addition to precision and productivity, CNC machines also offer greater flexibility in manufacturing. With the ability to program and reprogram different cutting paths and tooling, CNC machines can easily adapt to design changes and produce a wide variety of parts without the need for extensive retooling. This flexibility is particularly beneficial for companies with a diverse product range or those involved in prototyping and custom manufacturing.Moreover, CNC machines improve workplace safety by reducing the need for manual handling of heavy machinery and exposure to hazardous materials. This results in a safer and healthier working environment for employees, ultimately leading to higher employee satisfaction and retention.As a pioneer in the CNC industry, {} has been at the forefront of developing and implementing cutting-edge CNC technologies. Their machines are known for their reliability, precision, and user-friendly interfaces, making them a top choice for manufacturers looking to upgrade their production capabilities.In conclusion, the integration of CNC machining technology, such as the ones provided by {}, has significantly enhanced the manufacturing processes of companies across various industries. The precision, productivity, flexibility, and safety offered by CNC machines have not only improved the quality of the products but also increased the efficiency and profitability of manufacturers. As the demand for high-quality and complex products continues to rise, the role of CNC machining in the manufacturing industry will only become more critical, and companies like {} will continue to be at the forefront of this technological revolution.

Read More

Mastering the Art of Efficient and Accurate CNC Turning Operations

Title: Revolutionary CNC Turning Operation Amps up Precision in Metal Fabrication IndustryIntroduction:In today's metal fabrication industry, precision and efficiency are of paramount importance in ensuring high-quality products. In light of this, an innovative CNC turning operation has been developed to revolutionize the manufacturing process. This cutting-edge technique, coupled with the expertise and dedication of a renowned industry leader, promises to deliver unparalleled precision and flexibility in metal fabrication.Company Introduction (to be provided by the user):[Company name], a pioneer in the metal fabrication sector, has established itself as a trusted name renowned for its commitment to excellence. With a proven track record of delivering superior products and services, [Company name] has consistently pushed boundaries to provide innovative solutions to its customers. Backed by a team of highly skilled engineers and technicians, the company has always embraced cutting-edge technologies to stay ahead in the competitive market.News Content:In its relentless pursuit of innovation, [Company name] has recently incorporated a state-of-the-art CNC turning operation into its manufacturing process. This advanced technique not only enhances precision but also significantly increases productivity, making it a game-changer in the metal fabrication industry.CNC turning refers to the process of using computer numerical control (CNC) machines to create precise cylindrical and conical shapes in metal workpieces. Unlike traditional manual turning, which requires significant skill and time, CNC turning automates the process, enabling faster production cycles and improved accuracy. By precisely controlling various parameters like tool movement, feed rates, and spindle speed, CNC turning eliminates human error, resulting in consistent and superior quality products.The integration of CNC turning into [Company name]'s production line allows for enhanced precision across a wide range of metal components, including bolts, screws, shafts, pulleys, and more. With the ability to work with diverse materials, such as aluminum, steel, brass, and titanium, [Company name] can cater to the specific requirements of various industries, including aerospace, automotive, and engineering.One of the significant advantages of this cutting-edge operation is its versatility. CNC turning is compatible with both simple and complex geometries, making it suitable for a wide array of metal parts. [Company name]'s CNC machines are equipped with multiple tool stations and live tooling capabilities, enabling them to perform intricate operations like threading, grooving, and drilling in a single setup. This streamlines the production process, reduces lead times, and minimizes the need for additional machining operations, resulting in significant cost savings for customers.Moreover, [Company name]'s CNC turning operation ensures optimal efficiency. With its computer-controlled automation, the operation eliminates the downtime associated with manual tool changes and adjustments. Additionally, the integration of real-time monitoring systems and quality control measures provides continuous insights into the process, enabling prompt adjustments and ensuring consistent product quality.In line with its commitment to sustainable practices, [Company name] employs advanced software for programming and simulation. This digital approach enables precise material utilization, minimizing wastage and promoting environmental responsibility. By reducing material waste and optimizing cutting paths, CNC turning contributes to long-term cost savings, while also reducing the environmental impact of the production process.As [Company name] continues to leverage advanced technologies, the incorporation of CNC turning operation elevates its capabilities to new heights. With enhanced precision, versatility, and efficiency, the company is poised to meet the ever-growing demands of the dynamic metal fabrication industry.Conclusion:With the introduction of CNC turning operation, [Company name] has solidified itself as an industry leader committed to delivering excellence in precision metal fabrication. By embracing this cutting-edge technology, the company has elevated its production capabilities, offering unparalleled accuracy, versatility, and efficiency. With innovative solutions and a relentless pursuit of excellence, [Company name] continues to shape the future of the metal fabrication industry.

Read More

Exploring the Latest Prototyping Technology in China

The prototyping industry in China is undergoing a significant transformation, with the demand for high-quality prototypes and rapid manufacturing on the rise. As the global market increasingly relies on fast and reliable prototyping services, Chinese companies are poised to become major players in this industry.One such company leading the way in the prototyping industry is {Company Name}. Specializing in the development and production of high-precision prototypes, {Company Name} has established itself as a leader in the Chinese prototyping market.With state-of-the-art facilities and cutting-edge technology, {Company Name} offers a wide range of prototyping services, including CNC machining, 3D printing, injection molding, and low-volume manufacturing. Their team of skilled engineers and technicians work closely with clients to turn their ideas into reality, providing custom solutions for a diverse range of industries, including aerospace, automotive, consumer electronics, and medical devices.In recent years, {Company Name} has seen a surge in demand for their prototyping services, as businesses worldwide seek to shorten their product development cycles and bring new innovations to market faster. With their commitment to quality, precision, and efficiency, {Company Name} has positioned itself as a trusted partner for companies looking to prototype and manufacture their products in China.Furthermore, {Company Name} has made significant investments in research and development, continuously improving their prototyping capabilities and expanding their service offerings. By staying ahead of the curve and embracing the latest advancements in prototyping technology, {Company Name} has solidified its reputation as a forward-thinking and innovative company in the industry.As China's manufacturing sector continues to evolve, the demand for rapid prototyping and low-volume manufacturing is expected to grow exponentially. This presents an exciting opportunity for companies like {Company Name} to expand their reach and serve a global clientele.{Company Name} is well-positioned to capitalize on this trend, with their extensive experience, advanced infrastructure, and unwavering commitment to customer satisfaction. By delivering high-quality prototypes with fast turnaround times, {Company Name} has earned the trust and loyalty of clients around the world, setting the stage for further growth and success in the years to come.In conclusion, the prototyping industry in China is undergoing a period of rapid evolution, with companies like {Company Name} at the forefront of this transformation. With their dedication to innovation, quality, and customer service, {Company Name} is primed to become a key player in the global prototyping market, solidifying China's position as a leading hub for advanced manufacturing and rapid prototyping solutions.

Read More

Top Plastic Injection Manufacturers Providing High-Quality Products and Services

Title: Leading Plastic Injection Company Revolutionizes Manufacturing ProcessesIntroduction:In the ever-evolving world of manufacturing, innovative techniques and advanced technologies are crucial for staying ahead of the competition. One company that has successfully embraced these principles is a prominent plastic injection company. By establishing themselves as pioneers in the industry, they have revolutionized manufacturing processes, resulting in exceptional quality products and streamlined production timelines.Company Overview:The plastic injection company, (remove brand name), was founded in (year) with the vision of delivering cutting-edge solutions to industries ranging from automotive to consumer electronics. With an unwavering commitment to technological advancements, the company has consistently pushed the boundaries of what is possible in plastic injection molding. Through a customer-centric approach and a focus on sustainable practices, (remove brand name) has become a trusted partner for numerous renowned brands across the globe.Technological Advancements:In their quest for excellence, (remove brand name) has consistently invested in state-of-the-art machinery and innovative technologies. The company utilizes sophisticated computer-aided design (CAD) and computer-aided manufacturing (CAM) software to design and simulate the molds with utmost precision. This allows them to identify potential design flaws and make necessary adjustments early in the process, thereby reducing production costs and time.Furthermore, (remove brand name) has embraced automation to enhance efficiency and productivity. They have integrated robotics into their production lines to optimize repetitive tasks, ensuring consistent quality and minimizing human error. These cutting-edge technologies not only streamline the manufacturing process but also enhance the overall accuracy and repeatability of their products.Quality Control Measures:As a renowned plastic injection company, (remove brand name) places tremendous emphasis on maintaining the highest standards of quality throughout their manufacturing process. They employ a rigorous quality control program, starting from sourcing raw materials to the final inspection of finished products. By adhering to international quality certifications and utilizing advanced inspection equipment, (remove brand name) ensures that each product leaving their facility meets or exceeds customer expectations.Sustainable Practices:Recognizing their responsibility towards the environment, (remove brand name) has implemented various sustainable practices in their manufacturing processes. They adhere to strict recycling practices and promote the use of eco-friendly materials whenever possible. Through reducing waste generation and optimizing energy consumption, (remove brand name) minimizes their carbon footprint, contributing to a greener and cleaner planet.Collaborative Partnerships:A key factor behind the success of (remove brand name) is their collaborative approach with clients. By understanding the unique requirements and challenges of each customer, the company provides customized solutions that address their specific needs. From product design consultation to providing prototyping services, (remove brand name) actively collaborates with their clients, ensuring mutual success and establishing long-lasting partnerships.Plans for Future Growth:Looking towards the future, (remove brand name) aims to further advance their technological capabilities and expand their market reach. They plan to invest in research and development to drive innovation and continue delivering cutting-edge solutions to global industries. Additionally, (remove brand name) envisions strengthening their foothold in emerging markets, establishing themselves as a global leader in the plastic injection industry.Conclusion:Through their unwavering commitment to technological advancements, a customer-centric approach, and sustainable practices, (remove brand name) has revolutionized manufacturing processes. By consistently delivering high-quality products and optimizing production timelines, they have earned the trust and recognition of various industries worldwide. With their focus on future growth and innovation, (remove brand name) is set to redefine the plastic injection landscape and shape the future of manufacturing.

Read More

Growing Demand for 3D Printing Business Services Drives Market Expansion

3D Printing Business Expands Its OperationsThe 3D printing industry has been rapidly expanding over the past few years, with businesses and manufacturers turning to this innovative technology for cost-effective and efficient production. One company that has been at the forefront of this industry is [], a leading provider of 3D printing solutions.With a focus on delivering high-quality and precise 3D printing services, [] has recently announced the expansion of its operations to meet the growing demand for their products and services. The company has invested in state-of-the-art 3D printing technology, allowing them to offer a wider range of printing options and capabilities to their customers.[] has been a pioneer in the 3D printing industry, constantly pushing the boundaries of what is possible with this technology. The company's commitment to innovation and customer satisfaction has set them apart from their competitors, making them a trusted partner for businesses looking to bring their designs to life in a quick and cost-effective manner.The expansion of []'s operations comes at a time when the demand for 3D printing services is at an all-time high. Businesses across various industries, including aerospace, automotive, healthcare, and consumer goods, are increasingly turning to 3D printing for prototyping, production, and customization of their products. With this expansion, [] is well-positioned to meet the growing needs of these industries and provide them with the tools and support they need to succeed.In addition to their increased printing capabilities, [] is also focusing on expanding their reach to new markets and customers. The company has been actively engaging in partnerships and collaborations with businesses looking to harness the power of 3D printing for their own needs. By offering their expertise and resources, [] is enabling these businesses to leverage 3D printing to stay ahead in their respective industries.With their expanded operations and commitment to innovation, [] is poised to remain a key player in the 3D printing industry. Their dedication to providing high-quality, reliable, and cost-effective 3D printing solutions has earned them a solid reputation among their customers and partners. By continuously investing in new technologies and capabilities, [] is demonstrating their readiness to take on new challenges and push the boundaries of what is achievable through 3D printing.As the 3D printing industry continues to evolve and grow, [] is well-prepared to stay at the forefront and lead the way in providing cutting-edge printing solutions to businesses around the world. With their expanded operations and unwavering dedication to customer satisfaction, [] is set to carve out a larger space for themselves in this dynamic and exciting industry.In conclusion, the expansion of []'s operations signifies a significant step forward for the company and the 3D printing industry as a whole. As demand for 3D printing services continues to rise, [] is well-positioned to meet the needs of businesses across various sectors and provide them with the tools they need to thrive. With their focus on innovation, quality, and customer satisfaction, [] is proving to be a key player in driving the continued growth and success of 3D printing.

Read More

Unveiling the Latest Innovations and Advancements in CNC Metalworking

CNC Metalworking Continues to Revolutionize the Manufacturing IndustryIn the fast-paced world of manufacturing, precision and efficiency are key. One company has been at the forefront of revolutionizing the industry by utilizing CNC metalworking technology to create high-quality products with speed and accuracy. With their cutting-edge machinery and dedication to innovation, this company is poised to lead the way into the future of manufacturing.Founded in 1995, this company has been a driving force in the CNC metalworking industry for over two decades. With their state-of-the-art facilities and highly skilled technicians, they have been able to consistently deliver exceptional results to their clients. By investing in the latest advancements in CNC machining technology, they have been able to streamline production processes and enhance product quality.One of the biggest advantages of CNC metalworking is its ability to manufacture intricate parts with unparalleled precision. This level of accuracy ensures that each component produced meets the strictest quality standards. Gone are the days of human error and inconsistency. CNC machines can replicate designs with absolute fidelity, resulting in flawless and reliable products every time.Furthermore, CNC metalworking significantly reduces production time. With traditional methods, manufacturing even a simple part could take days or even weeks. However, with the implementation of CNC machinery, the time required to produce complex components has been drastically reduced. This accelerated turnaround time allows businesses to meet consumer demands more efficiently and stay ahead of their competition.The benefits of CNC metalworking extend beyond precision and speed. This manufacturing process also offers a range of material options to choose from. With the ability to work with various metals such as aluminum, stainless steel, and titanium, this company is able to cater to a wide array of industries and their unique requirements. From aerospace to automotive, medical to electronics, their CNC metalworking capabilities are limitless.Additionally, CNC metalworking is highly cost-effective. By automating the production process, this company can minimize labor costs and reduce material waste. With skilled technicians operating the CNC machines, errors are minimized, resulting in fewer defective parts. This not only saves time and money but also ensures that quality standards are consistently met.Furthermore, CNC metalworking eliminates the need for retooling between different jobs. Changing from one product to another in traditional manufacturing often required extensive setup and reconfiguration of the machinery. However, CNC machines can easily switch between jobs without any significant downtime. This flexibility allows for improved efficiency and increased production capacity.In order to stay at the forefront of the CNC metalworking industry, this company continually invests in research and development. By keeping a close eye on emerging technologies and trends, they can adapt and integrate the latest advancements into their production processes. This commitment to innovation ensures that they remain ahead of their competition and continue to offer cutting-edge solutions to their clients.As the manufacturing industry continues to evolve, CNC metalworking will undoubtedly play a crucial role in shaping its future. With its combination of precision, efficiency, and versatility, this technology is revolutionizing the way products are made. This company's dedication to excellence and their adoption of CNC metalworking continues to set new standards in the manufacturing industry.In conclusion, this renowned company has truly made a mark in the CNC metalworking industry. Their commitment to precision, efficiency, and innovation has allowed them to create superior products that meet the demanding requirements of various industries. With their state-of-the-art facilities and highly skilled technicians, they are well-positioned to continue leading the way in CNC metalworking. As the manufacturing industry moves forward, this company's dedication to excellence ensures that they will remain at the forefront of innovation and continue to shape the future of manufacturing.

Read More